With the rapid development of artificial intelligence and big data technology, what is the future trend of faucet production equipment peeling machines?

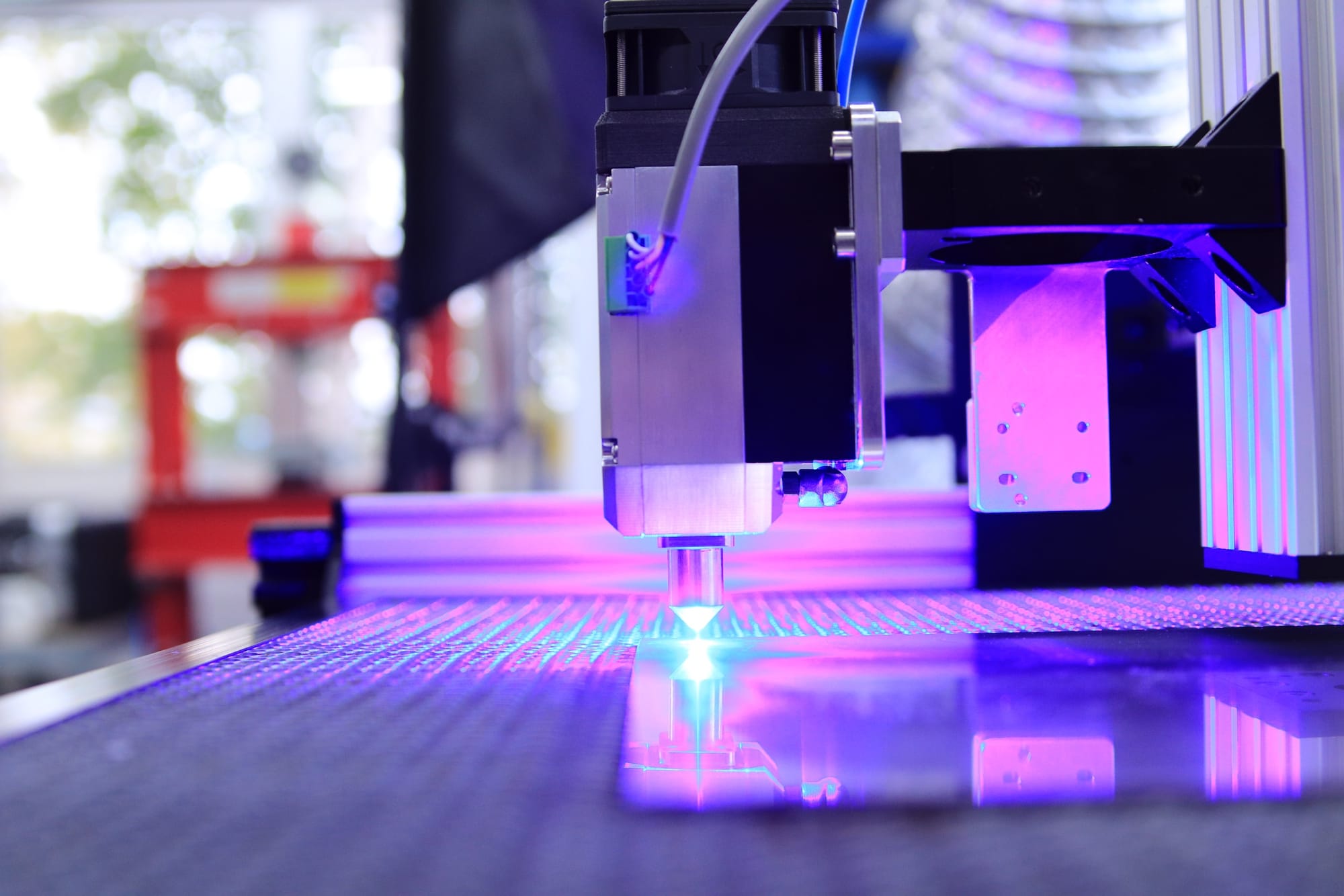

1. Intelligent manufacturing: With the rapid development of artificial intelligence and big data technology, CNC machine tools will pay more attention to intelligent manufacturing. It is expected that in the next few years, China faucet peeling making machine will usher in more intelligent and automated production lines, and the digital workshop will be further improved.

2. Growth in demand for high-end equipment: As the country has put forward higher requirements for high-end equipment manufacturing, in the next few years, the CNC machine tool industry is expected to see more growth in demand for high-precision, flexible customization and other aspects.

3. Green and environmentally friendly: Green and economical CNC system design will become the mainstream in the future. As the concept of environmental protection becomes more and more popular, CNC machine tool products will continue to be optimized to meet environmental protection standards.

4. Enhanced automation functions: In the future, CNC machine tools will pay more attention to the improvement of automation functions, including the development of automatic tool changing, automatic measurement and adaptive control, to achieve higher efficiency and reduce human intervention.

5. Digital manufacturing and industrial Internet: With the continuous development of industrial Internet technology, CNC machine tools will gradually realize digital manufacturing, improving production efficiency and quality through data analysis and intelligent optimization algorithms.

6. Increased demand for customization: As consumers’ demand for personalized products increases, CNC machine tools will also face more customized processing needs. Therefore, there may be more CNC machine tools designed for specific industries or specific products in the future.